To choose the best semi-automatic welding machine, you first need to decide who, why and how often it will be needed. The range of some manufacturers includes “amateur” and professional options, the difference in price between them is an order of magnitude. The best for a summer cottage and the best for a repair shop are different welding machines. A rating of semi-automatic machines, divided into categories, as well as an overview of the characteristics will help with your choice.

- Purpose of semi-automatic welding machine

- 5 best inexpensive household semi-automatic welding machines

- CET MIG/MMA-200A-1

- Edon Smart Mig 180

- ISA MIG-185

- ELITECH IS 160PN Promo

- Svarog REAL SMART ARC 200 (Z28303)

- 5 best inverter semi-automatic welding machines

- FoxWeld UNO MIG 180 COMBI

- Solaris MIG-206

- BRAIT MIG-250QD

- Wester TIG 220

- Quattro Elementi i-MIG 165

- 5 best semi-automatic welding rectifiers

- BLUEWELD Combi 4.135 Turbo, MIG/MAG

- BestWeld MASTER 132

- SOROKIN 12.16 - MIG 0.6-0.8mm 220V

- RedVerg RDMIG-195K

- Wester MIG 120, MIG/MAG

- 5 best semi-automatic welding machines with manual arc welding (MMA)

- START MIG183

- Wester MIG 140i

- Wert MIG 160

- Fubag IN 176 CEL

- RESANTA SAIPA-135

- 5 best semi-automatic welding machines with argon arc welding (TIG)

- GANTA MIG/MMA-200

- Aurora STICKMATE 205

- Grovers MMA 160G Professional

- TORROS MIG160 SUPPER

- BLUEWELD Prestige 186 PRO

- 5 best semi-automatic welding machines without gas on flux-cored wire

- Aurora Dynamics 2000

- Quattro Elementi MultiPro 2100

- ELITECH IS 250PN

- PTK MASTER MIG 200 F16 2020

- Fubag IRMIG 180 SYN

- 5 best professional semi-automatic welding machines

- Redbo PRO MIG-200 (3 in 1)

- AuroraPRO OVERMAN 180

- RUSELKOM TIG 400A MASTER (O)

- PTK RILON MMA 315 G

- BRIMA MIG/MMA-230 DIGITAL

- 11 popular manufacturers of semi-automatic welding machines

- Svarog

- Resanta

- Aurora

- Solaris

- Fubag

- Start

- Edon

- Brait

- Elitech

- Torros

- Foxweld

- Criteria for choosing a semi-automatic welding machine

- Device type

- Transformer

- Inverter

- Welding type

- MMA

- MIG/MAG

- TIG

- MMA+MIG/MAG, MIG/MAG+TIG – universal

- Input voltage (number of power phases)

- 220 V

- 380 V

- Universal 220/380

- Welding current

- Current adjustment range

- Output current type

- Variable

- Constant

- Open circuit voltage

- Cycle time

- Additional functions

- Anti-stick

- Hot start

- Arc Fast and Furious

- overheat protection

- Protection against power surges

- Protection against accidental connection to high voltage

- Reversing polarity

- Maintainability (availability of service centers, spare parts)

Purpose of semi-automatic welding machine

The semi-automatic welding machine is used for welding metal structures in a protective gas environment. The electrode is a wire that is fed to the welding site automatically by a special mechanism. In the sleeve, current, gas and wire are supplied to the working area. Such installations are suitable for domestic and professional use. The quality of welding is high, and even an untrained beginner can work, unlike welding machines that require experience to operate.

The semi-automatic machine copes with metals of different compositions (depending on the selected electrode, gas and mode), of different thicknesses. The purchase of such a device is justified both by a private owner at the dacha, and by a car service center or other small workshop.

5 best inexpensive household semi-automatic welding machines

For domestic use, a semi-automatic welding machine with a power of up to 3-5 kW is recommended. This indicator will be “extended” by a standard electrical network. And this is enough for working with non-critical connections, repairing metal structures with a material thickness of up to 2.5-4 mm, that is, for country and domestic needs.

CET MIG/MMA-200A-1

The compact and efficient device can work in MIG mode in a carbon dioxide environment, without gas with cored wire and with replaceable MMA electrodes. Its power is 5.8 kW. The operating current is adjustable in the range of 20-200 A. In gas mode, 0.6-1 mm wire is used, in MMA mode, 1.6-5 mm electrodes are used. The device operates from 198 V, and the open circuit voltage is 60 V. The 2.2 m cable and 2 m ground wire provide freedom of movement.

Ease of operation: one button control, indication of current values.

Metal wire feed drive, 5 kg reel.

Edon Smart Mig 180

This semi-automatic machine also operates in three modes: welding with gas protection, without gas with flux-cored wire and stick electrodes. The welding current with wire is 50-160 A, and with arc welding 20-160 A. For the convenience and safety of the operator, there is a welding mode controller with EMI protection. Operating parameters are stably maintained at a network voltage of 195-245 V. Smart Mig power is 5.6 kW.

The mechanism that moves the wire is protected from dust. Several layers of varnish are applied to the electronic components. There is protection against overheating and short circuit. These measures increase the reliability and service life of the device. The manufacturer equipped the device with a carrying strap and a spool of wire AWS E71T-GS 1 mm (powder).

Good value for money.

Convenient and understandable for beginners, suitable for home use.

ISA MIG-185

The small but powerful ISA MIG-185, according to its characteristics, is suitable not only for domestic use, but also for a small workshop or forge. All operating modes are available: gas, self-shielding wire and piece electrodes. Device power 5.5 kW. The operating current is enough to work with metal 1-5 mm, the welding current is 20-185 A, while the on-time at maximum current is 60%.

All fittings are 2 m long (burner, power and ground cables). The kit includes a spool of flux-cored wire.

Works well when the network voltage drops.

Excellent quality of work with electrodes, good quality with wire.

ELITECH IS 160PN Promo

This device is suitable for domestic use. It is inexpensive, compact, with a power of 3.7 kW. The welding current is adjustable in the range of 40-140 A. The device works with wire 0.6-0.8 mm, coil weight up to 1 kg. In arc welding mode, 1.6-4 mm electrodes are used. The device provides the ability to weld with flux-cored wire without gas. Open circuit voltage 55 V. This model does not have a carrying handle, but does have a shoulder strap.

Makes a good, neat seam in all modes.

High quality build.

Svarog REAL SMART ARC 200 (Z28303)

Ultra-compact, functional and quite powerful, Svarog works in 3 modes: in argon, with self-shielding wire and MMA piece electrodes. It is suitable for professional use too. Power 7 kW, operating current in all modes 20-200A. The device is not sensitive to voltage changes and operates stably at 140-270 V.

The intelligent control system Synergy MMA itself selects the optimal current based on the diameter of the electrode. Hot start allows you to get started faster and easier. The Antistick function prevents the wire from sticking. The device comes with a protective mask and mittens.The semi-automatic machine itself looks stylish and weighs only 3.8 kg.

Clear controls, many automatic functions.

Compact, well equipped.

Cooks well at low voltage.

5 best inverter semi-automatic welding machines

Semi-automatic welding machines are designed to work with wire in a gas environment. In this case, the wire is fed to the working element automatically. This simplifies the cooking process and reduces the number of auxiliary operations. At the same time, the seam turns out clean and neat even for beginners. Semi-automatic machines are widely used both by private households for domestic needs and for commercial purposes, for example in workshops. In both cases, the quality and speed of work are excellent.

FoxWeld UNO MIG 180 COMBI

Foxwell is a leader in the professional welding equipment market. The range of semi-automatic machines includes options such as UNO MIG 180 COMBI, suitable for non-commercial household use. However, the parameters allow you to work on the device in small-scale production, for example, in a workshop.

The device operates in MIG/MAG mode (0.6-1.0 mm wire) and arc welding with electrodes (1.6-3 mm). The welding current in the first option is 40-180 A, in the second 20-180 V. The duration of operation at maximum current is 60%. This model has the ability to adjust the inductance, which allows you to improve the quality of work and cook without splashing.

Professional level equipment, 5 year manufacturer's warranty.

High quality work.

Solaris MIG-206

There is an option to change the polarity, thanks to which you can weld with wire not only in a protective gas environment, but also without gas with cored wire. The device can also work with replaceable electrodes. Operating current with wire is 20-200 A, with electrodes 10-180 A.The power of the semi-automatic device is 3.7 kW, there is a filter protected from interference to surrounding equipment. The stability of the characteristics is guaranteed at an input voltage of 160-240 V. Thanks to the combination of these characteristics, the device can be powered from a regular 220 V network.

Solaris MIG-206 has a hot start function (no-load voltage 67 V), anti-stick, overload and overheat protection.

Many options for comfort (adjustments, protection against sticking, hot start) and safety (protections, filters).

Suitable for home use with professional specifications.

BRAIT MIG-250QD

This semi-automatic machine can handle even small production, for example, work in a car service center. The welding current range is large, MIG/MAG 30-250 A, and with stick electrodes 10-250 A. Productivity is excellent, operating time at maximum current is 70%. The operating current and wire speed are regulated with a digital display. The device has protection against overheating and overload. BRAIT MIG-250QD operates at a network voltage of 140-270 V.

High build quality, reliable.

Large range of welding current.

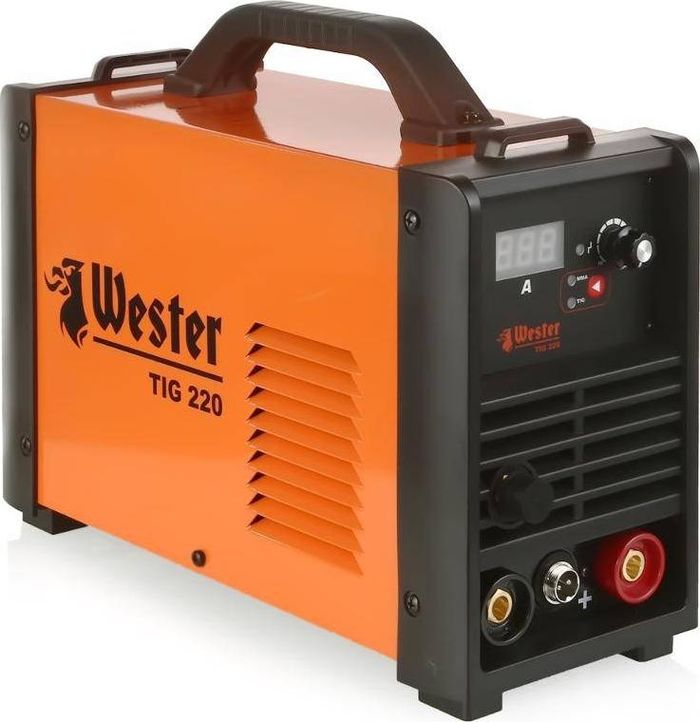

Wester TIG 220

It supports 2 operating modes: argon arc welding and arc welding with stick electrodes. The device is inexpensive, but the manufacturer positions it as professional. If you look at its characteristics, it turns out to be truly professional. Welding current 10-220 A in all modes, operation at maximum 70%. The diameter of the electrodes can be 1.6-5 mm. This semi-automatic machine copes with welding metals up to 8 mm. There are options such as hot start, antistick and arc afterburner. Device power 9 kW. It can operate when supplied with 120-260 V input.

The best price/quality ratio.

An excellent set of options, protection against overload and overheating.

High power.

Quattro Elementi i-MIG 165

Quattro Elementi i-MIG 165 can only cook in a gas environment in MIG/MAG modes with 0.6-0.9 mm wire. In terms of characteristics, this is more of a device for home use. Its power is 4.1 kW. The useful time is 30%, and the maximum welding current is 185 A. This is enough to solve issues of minor repairs of metal products in a country house or garage. The welding current is continuously adjustable. In case of overheating, the warning light comes on.

Good welding quality even with low current.

A good device that will last a long time.

5 best semi-automatic welding rectifiers

Semi-automatic rectifiers operate on direct current. To obtain it, a rectifier is included in the circuit. The result is high quality welds, without flakiness and spatter, and it becomes possible to work with cast iron and stainless steel. Devices of this format are technically simple and therefore very reliable. Most often they are used in production.

BLUEWELD Combi 4.135 Turbo, MIG/MAG

This rectifier operates in semi-automatic mode and welds wire in a MIG and MAG gas environment. The device is large, weighs 17.3 kg. The power is 3.6 kW, and the welding current is in the range of 50-120 A, while the useful time is 15%. Operating parameters are set with a certain step, stepwise. The diameter of the wire when working with gas protection is 0.6-0.8 mm, self-protecting 0.8-0.9 mm. The device comes with everything you need to get started and a wire for cooking without gas.

Inexpensive, but very reliable.

BestWeld MASTER 132

The Master series of semi-automatic devices from BestWeld operates on a single-phase 220 V network. Since 2015, the devices have been produced in several modifications for each model.If the index “A” is at the end of the marking, then the device is equipped with a modernized wire drive. Model power 4.7 kW. Operating current 40-120 A. Operating time at maximum current is 10%, when the current decreases to 65 A this is already 35%. The MASTER 132 rectifier operates in shielding gas, in MIG and MAG modes and with cored wire. Wire diameter 0.6-0.8 mm. Reel weight 5 kg. The device itself weighs 23 kg. For operator convenience, the device body is placed on wheels.

Ergonomic design.

High quality work.

SOROKIN 12.16 - MIG 0.6-0.8mm 220V

The manufacturer recommends this unit for working with thin sheet steel when high-quality, neat seams are needed. The power of the device is 5.2 kW. The welding current is regulated in steps in the range of 60-160 A. The magnitude of the welding current and the wire feed speed are mutually independent and controlled by the operator. Sorokin works with wire in gas and without gas. Wire can be used 0.6-0.8 mm. The device has overheating protection.

Convenient, flexible adjustments of operating modes.

Simple, easy to use.

RedVerg RDMIG-195K

The kit includes everything you need for welding, even a brush to clean up the scale. True, it practically does not form, since the RDMIG-195K works with gas protection of the working area. Welding current 40-180 A, operating time at maximum current 10%. You can select one of the proposed values for the operating current. Thanks to the ergonomic design and sufficient length of the fittings, this straightener allows you to cook in hard-to-reach places, even high up under the ceiling.

Makes clean, neat seams.

Reliable, works stably.

Wester MIG 120, MIG/MAG

The device is designed for welding metals up to 3 mm thick using MIG and MAG modes.Welding current is 35-120 A, at the maximum current value you can work for 1 minute without overheating. A well-thought-out ventilation system ensures high performance. The Wester MIG 120 can weld with wire 0.6-1.2 mm, the speed of its delivery to the working area is smoothly adjustable. You can operate from a 220 V network, with the input voltage reduced to 198 V. The manufacturer will add to the kit not only all the necessary cables, but also a brush and a protective mask.

High performance, suitable for industrial use.

Wide range of performance characteristics.

5 best semi-automatic welding machines with manual arc welding (MMA)

Arc welding allows you to work with a wide range of metals. In addition, you can cook with an arc in any position, and with the help of curved electrodes you can easily get into hard-to-reach places. MMA welding, on the one hand, is easier for beginners, on the other hand, it is better suited for professionals, as it has flexible adjustments in the process. The operator himself determines the current strength and the speed of the electrode.

START MIG183

This is a universal semi-automatic machine that welds with gas-protected wire and piece electrodes with an arc. The feature of the model is high accuracy of adjustment of operating parameters. Switching between modes is carried out with one button on the front panel of the device; the polarity is changed using the connector there. Welding current 30-180 A. Open circuit voltage 70 V. Long-term operation without overheating is possible thanks to constant forced ventilation.

In MMA mode it makes a beautiful, clean seam.

Convenient controls.

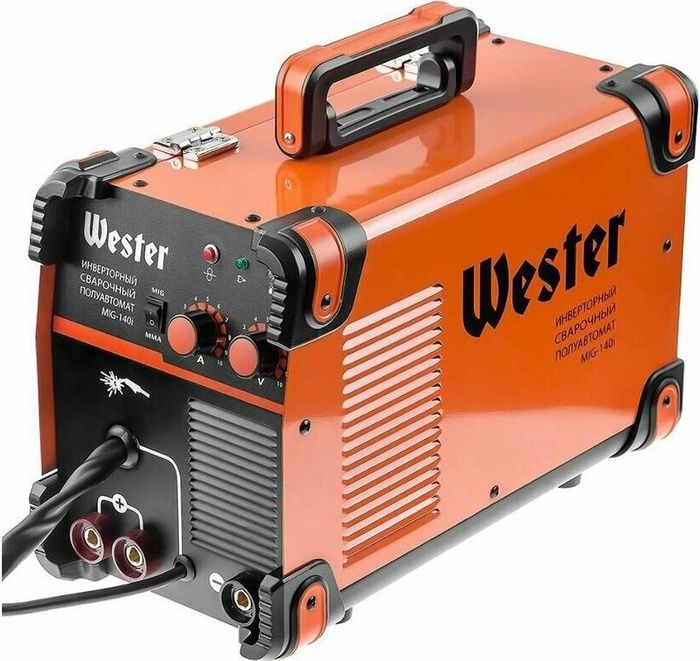

Wester MIG 140i

This model connects to a 25 A power outlet. The power of the device is 4.7 kW. The Wester MIG 140i cooks at a constant current of 40-140 A. The useful time is 60%.For efficient and comfortable welding, the hot start and arc afterburner options have been added. The device operates in MIG mode with 0.6-1 mm wire, and in MMA mode with 1.6-3.2 mm electrodes. The price-quality ratio is on the buyer’s side, thanks to which the model is in demand. The kit includes a wire for working with gas and a protective mask.

Holds the arc stably.

High quality for a reasonable price.

Wert MIG 160

Wert MIG 160 is not harmful to the quality of the power supply and operates stably from the network at 140-250 V. The power of the unit is 3.30 kW. This semi-automatic device supports cooking modes with active and inert gas, without gas with flux-cored wire and arc welding with electrodes. The wire used is 0.6-0.8 mm, electrodes are suitable for 1.6-4 mm. Welding current in all modes is 30-160 A, the device copes equally well with thick and thin sheet metal. Operating time at maximum 60%. Reel for 5 kg, diameter 100/200 mm.

Smooth adjustment of all operating parameters.

Good quality seams in MMA mode.

Fubag IN 176 CEL

An ultra-compact and very functional semi-automatic machine operates in MMA and TIG modes. Welding current 19-160 A is regulated by touch keys with digital display. Useful time 65%. Fubag IN 176 CEL has many useful options: hot start, anti-stick and Tig Lift. The device works with 1.6-4 mm electrodes, including cellulose electrodes.

The weight of the device is only 4.9 kg; a shoulder strap is provided for carrying. The design is bright, yet ergonomic: everything is clear and understandable. Bayonet connectors.

German quality in everything: good assembly, stable operation.

There are many options that make it easier to configure and operate the device.

RESANTA SAIPA-135

This semi-automatic machine has excellent performance indicators.Works with gas and in MMA arc welding mode. With a stated current of up to 110 A, it welds metal up to 3 mm well. Load duration at a maximum current of 70%, one of the best indicators among competitors. If you believe the instructions, then Resanta works with an input voltage of 140-270 V. Despite the relatively low cost of the device, “utilities” are provided: hot start, anti-stick and controlled arc afterburner. There is a protective indication against overheating.

Excellent functionality for a reasonable price.

Stable operation even with unstable network voltage.

5 best semi-automatic welding machines with argon arc welding (TIG)

For welding aluminum, copper, magnesium and their alloys, various types of stainless steel, bronze, titanium and other metals, the TIG method is used - arc welding with a non-consumable electrode in a protective argon environment. This type of welding is professional and requires some experience and skill of the operator. In particular, for a smooth, stable arc, the tungsten electrode must be sharpened before each operating cycle. The TIG mode is supported by some universal semi-automatic machines.

GANTA MIG/MMA-200

The inverter semi-automatic Ganta cooks at direct current in the range of 20-200A. The device supports all possible types of welding: wire in a gas environment, without gas, tungsten electrodes in argon and MMA stick electrodes. Effective time ratio 60%. To ensure smooth running there is a gear heater. The wire suitable for this device is 0.6-0.8 mm, the coil size is 1 kg. Electrodes can be used 1.6-4 mm. The device itself is compact, weighing 10 kg. There is a convenient handle on the case for carrying. There is protection against overload and overheating.

Smooth adjustment of operating parameters over a wide range.

Good performance.

Aurora STICKMATE 205

STICKMATE 205 works with electrodes in two modes: arc-coated electrodes and non-consumable electrodes in an argon environment. The power of the device is 6.5 kW. The working current for argon-arc welding is 10-200 A, for gasless arc welding 40-200 A. The diameter of the electrodes is 1.6-5 mm. Basic, rutile, cellulose electrodes are suitable for welding with Aurora. This model has a function against electrode sticking, hot start, arc forcing and automatic voltage reduction with an inactive electrode (VRD). The device is

compact and lightweight, its weight is 4.3 kg, it is powered by a single-phase 220 V network.

Soft, flexible arc with all electrodes.

Lightweight and compact device.

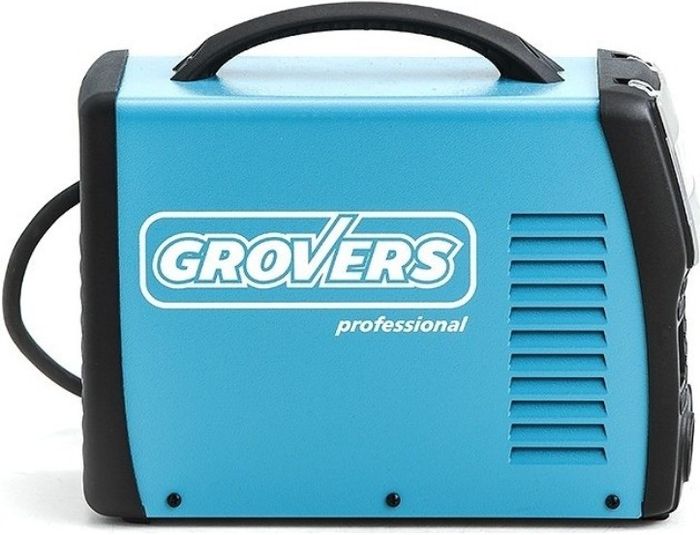

Grovers MMA 160G Professional

The Grovers MMA 160G inverter is designed for manual arc welding at different polarities, as well as argon-arc welding. This is a compact, quiet device, powered by a single-phase network with a voltage of 160-270 V. It is powerful, efficient, but very quiet thanks to IGBT technology. The housing is shockproof, there is a protective visor on the control panel.

Welding current 10-160 A, there is an anti-stick, hot start, TIG welding start from the first point and arc force. Useful time 60%. Idle voltage 67 V. The characteristics and quality of work of this model are professional level.

Reliable, strong.

High quality of the seam, welds without splashes.

TORROS MIG160 SUPPER

TORROS MIG160 SUPPER is suitable for both private household use and professional production. This is an inverter semiautomatic machine with extended functionality. There are modes of welding with wire in a protective gas environment, without gas, arc and argon-arc welding.Good performance.

Aurora STICKMATE 205

STICKMATE 205 works with electrodes in two modes: arc covered electrodes and infusible electrodes in an argon environment. The power of the device is 6.5 kW. The operating current for argon arc welding is 10-200 A, for gasless arc welding 40-200 A. The diameter of the electrodes is 1.6-5 mm. Basic, rutile, and cellulose electrodes are suitable for Aurora welding. This model has a function against electrode sticking, hot start, arc force and automatic voltage reduction when the electrode is inactive (VRD). Device

compact and lightweight, its weight is 4.3 kg, powered by a single-phase 220 V network.

Soft, flexible arc with all electrodes.

Lightweight and compact device.

Grovers MMA 160G Professional

The Grovers MMA 160G inverter is designed for manual arc welding of different polarities, as well as argon arc welding. This is a compact, quiet device, operates from a single-phase network with a voltage of 160-270 V. It is powerful, efficient, but very quiet thanks to IGBT technology. The case is shock-resistant, there is a protective visor on the control panel.

Welding current is 10-160 A, there is an anti-stick, hot start, TIG welding stratum from the first point and arc force. Useful time 60%. Open circuit voltage 67 V. The characteristics and quality of work of this model are of a professional level.

Reliable, strong.

High quality seam, welds without splashing.

TORROS MIG160 SUPPER

TORROS MIG160 SUPPER is suitable for both private household use and professional production. This is an inverter semi-automatic machine with advanced functionality. There are wire welding modes in a protective gas environment, without gas, arc and argon-arc welding.Automatic adjustment of the welding current and wire feed speed depending on voltage and diameter will make life easier for beginners, and the ability to manually fine-tune it will make life easier for professionals. There are 3 preset modes.

Welding current for working with wire is 30-160 A, arc 20-140 A. The diameter of the wire is 0.6-1 mm, and the diameter of the electrodes is 1.6-3.2 mm. There is an accelerated wire threading mode. All operating indicators are displayed on a digital indicator. There is also protection against overheating and internal failures with automatic shutdown of the welding current.

Automatic settings with manual adjustment, preset programs.

Wide range of possibilities.

BLUEWELD Prestige 186 PRO

The device is designed for welding steel, including stainless steel, cast iron using MMA and TIG arc welding. The model operates from a 220 V network and gives stable output values when the input voltage fluctuates within 15%. Device power 4 kW. Operating current 20-160 A, electrodes 1.6-4 mm. Operating time at maximum current is 60%; if the inverter overheats, a protective shutdown is triggered. The device provides hot start, anti-stick and arc afterburner.

Works stably in different climatic conditions, with unstable input voltage.

Italian quality and style.

5 best semi-automatic welding machines without gas on flux-cored wire

Welding with self-shielding wire is used for different types of steel. Despite some disadvantages, for example, slightly lower weld quality than with gas welding, working with flux-cored wire can be the best choice. With this type of welding there is no need to use a massive gas cylinder. This is an excellent solution for working in hard-to-reach places and at heights.For private owners who use welding occasionally, this option is also better: you don’t need to buy and store a cylinder somewhere, preparation for work is easier. Flux-cored wire is more expensive, but in the situations described above, its purchase is also justified economically.

Aurora Dynamics 2000

A wide range of operating current allows you to weld metals of different thicknesses. The current is adjustable in the range of 30-180 A. The peculiarity of this model is the quality and stability of operation not only at high current levels, but also at low ones. The ability to control the inductance allows the operator to achieve the desired dynamics of the welding arc. Adjustments of all operating parameters are smooth, stepless, using rotary switches. The display is digital, there is a safety alarm and shutdown when overheating. The kit includes a roller for steel wire 0.6-0.8 mm. To work with self-shielding wire, you need to purchase an additional feed roller.

It welds metals of any thickness equally well.

Comfort options: anti-sticking protection, low current stabilization and hot start.

Reliable, well-built, well-thought-out device.

Quattro Elementi MultiPro 2100

The company is looking for the best solutions all over the world for its equipment. Welding inverters contain high-speed bipolar transistors from leading manufacturers Fairchild Semiconductor (USA) and Infineon Technologies (Germany). They are the basis and provide exceptional reliability and durability. Highly efficient fans are used for cooling, which increases the performance of the device. The device is universal in its range of functions: it supports MIG/MAG, TIG and MMA modes. Welding current 30-190 A when working with wire at different polarities, 30-160 A when arc welding. Among the “conveniences” there is arc afterburner.Device power 4.9 kW, power supply 220 V.

Great attention to the quality of components.

Compact but with a wide range of functions.

ELITECH IS 250PN

Good build quality.

Simple and easy to use.

Universal: works in all types of welding with good seam quality.

PTK MASTER MIG 200 F16 2020

The device works with wire, including polarity reversal, and piece electrodes. Welding current of 20-200 A allows you to solve problems of varying complexity. In addition to the current, the operator can adjust the “hardness” of the arc by manually changing the inductance. The power of this Master is 3 kW, powered from a 220 V network. The device is assembled taking into account the principles of energy efficiency. High-quality cooling increases productivity, and overheating protection guarantees long, uninterrupted service. Manufacturer's warranty 24 months. The device is compact and relatively light (8 kg). The idle wire drawing key is located on the control panel. There is also a warning light here in case of overheating.

The gearbox that feeds the wire is metal.

High quality materials and workmanship.

Flux cored wire welding at height.

Fubag IRMIG 180 SYN

This model is positioned by the manufacturer as professional and is recommended for work on a construction site or in a workshop. The device allows you to weld not only with wire (including self-shielding), but also with piece electrodes. When working in an inert gas environment, you can use automatic selection of operating current and voltage values. Welding current 15-200 A (+/-10 A for different modes). Forced continuous cooling increases the operating time before overheating. Duration of operation at maximum current 40%. The coil of wire stands at 5 kg, with a diameter of 200 mm.

The length of the fittings is 3 m and its flexibility allows you to reach hard-to-reach places.

According to reviews from professional craftsmen, the quality of welding and ease of setup are very good.

5 best professional semi-automatic welding machines

Professional equipment, which is a tool of labor, requires high productivity, quality of work, stability of performance indicators regardless of environmental factors, and reliability of the equipment itself. The equipment must be either universal, suitable for solving the entire range of welding tasks in a given production, or, conversely, capable of carrying out specific, highly specialized operations.

5 Best Narrow Washer Dryers - Ranking

Redbo PRO MIG-200 (3 in 1)

A device with many professional gadgets. It is universal in purpose, works with both wire and electrodes. Wire diameter 0.8-1 mm in reels 1-5 kg. The manufacturer guarantees stability of performance at an input voltage of 185-250 V; in the event of surges in the network, the welding arc is automatically stabilized.

Welding current 50-200 A.There are options such as anti-stick, hot start, arc force, gas purging before and after work, as well as BURN BACK, in which the wire is returned to fill the formed crater and the last drop is reset, so that the end of the wire is immediately ready for the next work cycle. The operator can adjust the current, voltage, inductance, material feed rate and arc force.

Lots of professional options.

Versatility.

Reliability and quality, 36 month manufacturer's warranty.

AuroraPRO OVERMAN 180

AuroraPRO OVERMAN 180 is an inverter semi-automatic machine for working with wire in a gas environment. The inverter, based on MOSFE technology, provides excellent performance. Welding current is 40-175 A, welds metal 0.5-5 mm without problems. The wire length is 0.6-1 mm, the feed mechanism is metal, there is an option for wire drawing. You can weld aluminum.

All controls, including the power key, are located on the front panel. You can adjust: current, voltage, inductance, wire speed. The sleeve is articulated and comfortable.

Good ergonomics, the ability to manually adjust all operating parameters.

RUSELKOM TIG 400A MASTER (O)

The machine for argon arc welding (it is possible to weld with coated electrodes) is suitable for working with non-ferrous metals, different types of steel, copper, titanium, and alloys based on them. Welding takes place using direct current. Operating current 20-400 A, Master RUSELKOM TIG 400A can cope with metal up to 17 mm. Device power 13 kW. There is protection against overheating and power surges in the network. The operating parameters are smoothly adjusted; this can be done from the remote control.

Professional equipment for working with a wide range of metals up to 17 mm.

High quality from a domestic manufacturer, one of the market leaders.

PTK RILON MMA 315 G

This is an inverter arc welding machine. The welding current of 40-315 A is smoothly adjustable, the accuracy of the settings is ensured by PWM technology. The device operates from a three-phase 380 V network. The working boards are divided into blocks, the protective alarm (thermal sensors) is connected only to the block with transistors, which heat up more than others during operation. This solution allows you to avoid “false alarms”, because the alarm is triggered only when the power elements actually overheat. An efficient tunnel cooling system increases the performance of the device. If desired, the device can be equipped with a remote control panel.

The device has a 5-year warranty.

High quality welds.

BRIMA MIG/MMA-230 DIGITAL

The universal semi-automatic machine is capable of welding metal with a thickness of 0.8 mm. Welding current is 20-230 A. The device operates at maximum current 60% of the time. Operating parameters are displayed on a digital display. The front panel contains controls, power-on indication and a safety alarm (against overheating). Brima is connected to a single-phase 220 V network. Changes in input voltage within 10% do not affect welding parameters.

Good value for money.

High performance.

11 popular manufacturers of semi-automatic welding machines

When purchasing welding equipment, you should pay attention to devices from those manufacturers who have sufficient experience in this sector. For equipment that operates at high voltages and temperatures, it is important to be reliable and operate without interruption.Market leaders have developed technologies and brought quality to perfection.

6 best professional chainsaws - rating

Svarog

The Svarog brand hides products from the Chinese manufacturer Shenzhen Jasic Technology. For the domestic market, it produces semi-automatic devices under the name Jasic, and for ours under the Svarog brand. The models are absolutely identical. The manufacturer uses advanced developments from Toshiba, Siemens and other gurus in its production. This is a highly specialized production that deals only with welding equipment. Over 15 years, quality has reached the highest level. Users speak of Svarog semi-automatic devices as reliable and functional.

Resanta

The brand is the leader of the Russian market. About 50% of semi-automatic welding machines sold in 2017 were from Resanta. The equipment is produced in Latvia and complies with all European quality standards and technical regulations. The brand's high-quality semi-automatic machines, in the middle price segment, are available to a wide range of buyers. A big advantage of the brand is a wide network of representative offices in the CIS.

Aurora

The Aurora group of companies offers a wide range of welding equipment from “amateur” models to professional ones. Since 2012, the Chinese market leader Riland has joined Aurora. By combining experience and developments, the company reached the top of the ratings in the sector. Despite the fact that the devices cost more than average, they are in demand.

Solaris

Belarusian equipment is known for its quality and reliability. Solaris semi-automatics are no exception. All devices are assembled with high precision and high quality. At the same time, they meet modern requirements and have all the necessary options for both domestic and professional use.The design of the equipment is very nice. With equal characteristics, Solaris semi-automatic machines are slightly cheaper than their analogues.

Fubag

The German brand Fubag has been producing equipment for construction and renovation for about 50 years. The company has 19 plants in Europe. Fubag cooperates with leading designers and technical designers and has its own developments. The brand’s semi-automatic welding machines are efficient in operation, are perfectly customizable, and allow you to make high-quality seams in any welding mode.

Start

Equipment is produced on a production line in China under the strict supervision of Start from Russia engineers. Protective equipment for welders is manufactured at our own plant in Kazan, opened in 2018. Start semi-automatic welding machines are distinguished by their bright design, thoughtful functionality and high quality.

Edon

The Chinese manufacturer, 60% of whose product range consists of welding equipment, is focused mainly on the Russian consumer. The company has 3 of its own production and research centers. There are many representative offices of the company in our country. Customer focus is Edon's strong point. Specialists accompany the client from the moment of equipment selection, purchase and further during operation. The brand’s welding machines are affordable to a wide range of consumers. They are chosen for infrequent household use.

Brait

This is a Russian supplier of Chinese equipment. Representatives of the Brait company select partners who meet high quality requirements and produce welding equipment according to European standards. Semi-automatic welding machines are made in a single, bright design. They are functional and reliable enough to become popular. The price-quality ratio is acceptable.

Elitech

Another Russian company is represented in the list of the best manufacturers of welding equipment. Elitech says professional-grade equipment can be inexpensive. The emphasis is on durability and quality. The line of semi-automatic welding machines includes household models at the price of a blender, and there are also professional powerful units that can satisfy the welding needs of large-scale production.

Torros

This brand produces professional construction equipment: machines for arc and semi-automatic welding, laser cutting, etc. Bright, modern design with thoughtful ergonomics sets Torros equipment apart from its competitors. Even the basic models apply the principle of synergetic control. According to some reports, the brand is Japanese, while it is reliably known that the production of the equipment is located in China. With proper quality control, this move allows you to reduce production and logistics costs, while maintaining quality in the declared sector.

Foxweld

And another one of our companies, which is produced in China. Foxweld produces semi-automatic welding machines from simple household and semi-professional models to super-functional options that can weld armor. In its activities, the company focuses on innovation and reliability. Foxweld was the first to launch a device with full automatic control and double impulse. For each group of products there is a production line with its own quality control. The welding equipment is guaranteed for 5 years.

Criteria for choosing a semi-automatic welding machine

Experienced professionals who know what they want to get from the equipment will easily choose the best option for their tasks. It will be more difficult for a beginner in welding.The range of semi-automatic machines is huge. They are all different in type, purpose, characteristics.

When welding workers, the welding current is a factor. You can get it using a transformer or inverter. Each type of device has advantages and disadvantages.

Transformer

The technology has been proven not for years, but for a whole century of testing. Technically, the device is simple and therefore very reliable. Exceptional reliability and unpretentiousness are the main advantages of transformers. Another thing is the low price. A welding machine of this type is harmful to the quality of food, but is completely indifferent to working conditions. In the cold, in a dusty workshop, only he can work. Transformers are chosen when the quality of the seam does not matter, but high performance is important.

Inverter

The inverter allows you to obtain stable output current readings with fine adjustment and quality control. This expands the capabilities of the welding machine. This makes the device compact, energy efficient and easy to use. Inverter semi-automatic welding machines support all welding modes: with and without wire in gas, covered arc and infusible electrodes, depending on the model, all at once, or only some. Such devices operate stably even with significant voltage drops in the supply network, and allow you to make clean, neat seams with pinpoint precision.

Welding type

Depending on what metals need to be welded, their thickness, and the requirements for the quality of the weld, different types of welding are used.

MMA

Electric arc welding with coated piece electrodes. Replaceable electrodes, usually 1.6-5 mm thick, have a coating that melts and releases gas during operation.The latter forms a protected zone around the operating point. This type of welding is suitable for both beginners and professionals and allows you to solve a wide range of problems. Electrodes are consumables.

MIG/MAG

This is the same semi-automatic welding. The wire is fed into the work area, as well as an inert gas, such as argon (MIG), active gas (MAG) or a mixture of both. The gas displaces oxygen from the welding zone and prevents oxidation. The seam turns out clean, without scale. The welding itself is done manually, but the wire is fed into the work area automatically. When changing the polarity, the device can cook without gas, using self-shielding wire. Inside the hollow wire there is a powder that, instead of gas, protects the welding area.

This type of welding is easier to learn, suitable for domestic use; most machines operate on a single-phase network. Beautiful, strong seams are obtained almost on the first try.

| TIG | This is arc welding with a non-fusible tungsten electrode. For protection, gas is supplied, as when working with wire. This type of welding is designed to work with various alloys of copper, titanium, and all types of steel. Typically, the TIG mode is added to others in universal devices or supported by professional equipment. | 6 best semi-professional chainsaws - rating |

| 1,6 | 1-2 | 25-50 |

| 2 | 2-3 | 40-80 |

| 3 | 3-4 | 90-140 |

| 4 | 4-6 | 140-200 |

| 5 | 6-8 | 180-250 |

MMA+MIG/MAG, MIG/MAG+TIG – universal

If there is a need to work equally with different types of welding, the best option is a universal machine. More popular semi-automatic machines can cook with piece electrodes without gas, that is, the device will be MIG/MAG with MMA support. There are models that can work in all 4 modes, including TIG. Universal semi-automatic machines are produced by manufacturers, both inexpensive household and professional ones.

Input voltage (number of power phases)

On sale you can find devices operating from a 220 V and 380 V network.

220 V

Devices operating on a 220 V network are suitable for private use, in the garage or country house, and for commercial purposes, for example, in a “garage service” or other small enterprises. Manufacturers make every effort to ensure that these devices cook equally well with any network quality, without causing significant sagging. The power of the devices can reach 4-5 kW.

380 V

Professional equipment operates on a three-phase 380 V network. The power of such devices can reach 10-15 kW. These semi-automatic welding machines can weld metal of almost any thickness. Connecting to the mains allows you to work without worrying about the input voltage.

Universal 220/380

Devices operating from any network are rare, but they do occur. Such versatility is needed, for example, for mobile services. Devices operating on 380 V can be connected to a single-phase network through the adapter that comes with them.

Welding current

The value of the welding current shows how thick the metal can be welded in this mode. The relationship is direct: more current, thicker the metal. The current is selected according to the table.

Electrode, mm

Metal thickness, mm

Welding current, A

Current adjustment range

The welding current is adjustable over a fairly large range so that the operator can choose the optimal value for a specific task. The larger this range, the more functional the device.

Output current type

The quality of the seam depends on the current with which it is welded. The smoother, more stable the current, the nicer the seam will be.

Variable

Automatic welding machines convert the input current into a higher frequency one, suitable for welding metals. In simple models intended for domestic use, this is where the work (conversion) with current ends. The absence of a rectifier simplifies and reduces the cost of the design.

Constant

On most devices, there are rectifiers after the transformer or inverter. Some manufacturers leave the operator the right to choose which current to work on. With direct current, the weld is smooth, without flaking, and the metal spatters less. The presence of a rectifier does not greatly affect the cost, but increases the dimensions of the device.

Open circuit voltage

Open circuit voltage shows what voltage will be on the terminals at the moment when there is no arc on them. The higher this value, the easier the electric arc appears, the easier it is to start cooking. In inexpensive models this value is 40-55 V. In professional ones it can reach 65 V. In modern semi-automatic machines the VRD function is found. It automatically reduces the no-load voltage during idle moments to 12-20 V, that is, to values that are safe for the operator.

Cycle time

This value shows what fraction of a 10-minute cycle the device can operate at maximum current. This value essentially determines the performance of the semi-automatic machine. In a professional environment, the operator cannot afford long pauses and chooses a device with a duty cycle of 50% or more. Some manufacturers refer to this value as “useful time” in their documentation.

Additional functions

For comfortable work, to relieve the operator of some of the worries, as well as to ensure the safety of both equipment and the user, manufacturers pump up devices with useful functions.

Anti-stick

During welding, it happens that the electrode or wire melts to the working area and more current begins to flow through it than necessary. The antiatick function detects the initial moment of this situation and reduces the current and voltage on the electrode so that the operator can safely move it to the next point. This option is especially relevant for beginners.

Hot start