Items of clothing often act as the owner's calling card. A perfectly ironed men's suit and a perfectly fitting women's jacket add a lot to a positive image. Therefore, the time spent on ironing a jacket pays off handsomely.

Is it possible to iron a jacket?

The answer to this question should be found on the care label. If there is an iron symbol on the tag, the jacket can be ironed at the recommended temperature. If the iron in the picture is crossed, it is not possible.

This prohibition is not always absolute: in most cases it indicates the inadmissibility of ironing in the traditional way, that is, by pressing a heated surface, but does not prohibit the use of steam.

The label indicates not only the fundamental possibility, but also the recommended temperature:

- one point – ironing is allowed at a minimum temperature, from +90 to +115 degrees;

- two points – from +120 to +140;

- three points - the recommended heating temperature of the iron is from +160 to +200.

Such a wide tolerance is explained by the fact that, firstly, the temperature of the procedure is determined by the composition of the material, and secondly, by the fact that the temperature scale of different iron manufacturers is different, and this must be clarified in the instructions.

Ironing tools

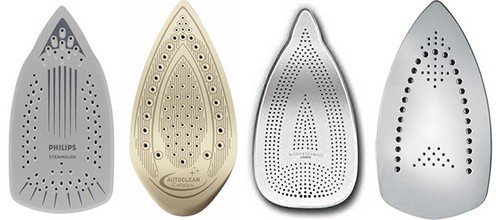

- Iron – it is recommended to use a model with good vertical steam. An equally important issue is the type of sole. The majority of aluminum surfaces will require the use of protective equipment - a flat iron, damp gauze.The steel sole, especially the one with spraying, is more gentle on the fabric, however, at high temperatures, protective agents are necessary. Ceramic behaves similarly to steel: it loses the ability to maintain the structure of the fabric as the ironing temperature increases.

- Ironing board – jacket can be ironed on the table, but it is more convenient to do this on a board with its small width.

- An ironing sleeve is a small board with a curved shape.

- Spray bottle, wet gauze.

Ironing sequence

The difficulty of caring for a jacket lies in the number of parts and the need to ensure complete preservation of its shape. And since the composition of the fabric of the jacket and its lining are noticeably different, and they react differently to the effects of temperature, the danger of ruining the product by unsuccessful ironing increases.

The damp cloth between the soleplate of the iron and the fabric serves as a kind of buffer that reduces this difference.

- The product must first be cleaned of dirt and dust. When exposed to temperature, the dust burns and turns into tiny but very noticeable soot particles.

- The product is placed on the ironing board, straightened out, the pockets are turned out and ironed from the wrong side.

- The sleeves are ironed next: the fabric is moistened if necessary, the sleeve is placed inside the sleeve, the piece of clothing is ironed until completely dry.

- The hangers are processed from the reverse side, after preliminary moistening or steaming. If available, use a shoulder pad.

- The selections are steamed and ironed until dry.

- The back and shelves are ironed from the front side, and wet gauze must be used.

- The lapels of the jacket and collar are ironed first from the inside and then from the face. In order to prevent the formation of gathers when ironing on the front side, the fabric is slightly stretched.

The direction of movement of the iron is determined by the texture: if the material is smooth, then ironing begins from the bottom, if it is fleecy, then from top to bottom.

Steaming

If the iron is powerful enough and the vertical steaming function does not cause any complaints, caring for the jacket comes down to steam treatment.

- The product is placed on a hanger or a special rack, cleaned of dust and straightened.

- Special inserts or tightly rolled cotton towels are placed in the sleeves.

- The jacket is treated with a jet of steam at a distance recommended by the instructions, from top to bottom if it is made of fleecy fabric, and from bottom to top when it is made of smooth fabric.

A steam generator or an iron with a steam generator gives excellent results. The power of the steam jet is much higher, and it will take less time to bring the jacket to perfect condition.

For products with embroidery, sequins, beads and the like, using a steam generator is the only possible care option.

Features of ironing jackets made from different fabrics

The composition and characteristics of the material are important not only for determining the ironing temperature, but also affect the procedure itself.

Linen and cotton models

These fabrics are resistant to temperature and steam, which creates certain difficulties during care.

- Ironing is performed at high temperatures – +200–+230.

- It is recommended to iron the jacket slightly damp and moisturize it during the procedure.

- It is impossible to achieve the ideal look of fabric: clothing manufacturers and fashion trendsetters are well aware of this, so some wrinkles in the products are allowed.

If the jacket has a lining, it is necessary to reduce the temperature to the one recommended for the fabric of the lining. This will increase the ironing time, but otherwise the material may shrink higher than the jacket fabric, which will lead to deformation.

Wool jacket

The greater the amount of wool in the fabric, the more carefully you should handle the product.

- The use of damp gauze or thin cloth is mandatory.

- The iron is applied to the surface of the product, rather than sliding along it, especially in the area of the seams.

Fabric products with patterns

No less care should be taken when handling items made from corduroy, velvet, mixed fabrics with a fleecy surface, or with a relief pattern.

- To prevent damage, proceed in the same way as in the previous case, that is, apply the iron rather than move it.

- If it is necessary to iron the front side of the jacket sleeve, a multi-layer backing is used.

- It is advisable to moisten the product using steam or sprinkling gauze.

Silk jackets

It is not recommended to iron clothes made from natural silk. As a rule, manufacturers indicate this in the appropriate labeling. Artificial silk is not so demanding: it is ironed at low temperatures and is moistened only with steam. Spraying causes stains to appear.

Artificial and synthetic fabrics

The best source of information is the product label.Modern technologies change the quality of raw materials, both natural and artificial, beyond recognition, so without first studying the tag it is difficult to answer accurately.

As a rule, synthetic fabrics are less resistant to heat, but in practice this property largely depends on the density and processing method.

For example: viscose fabric is made from artificial fibers, but it is not recommended to iron thin viscose fabric at all.

Modern modifications of polyester - synthetic fabric, are resistant to heat. As a result, a summer jacket made of delicate fabric must be ironed at temperatures up to +160 degrees. And since polyester is non-hygroscopic, steaming does not make ironing easier.

The most proven tool for determining the optimal ironing mode remains a practical test. Usually a piece of fabric is attached to the side seam of the jacket. It is recommended to use it as a control sample.

Thanks a lot. Very useful!