In suburban areas there is often no supply of cold drinking water. People get out of this situation by building a well on their property. But one fine day, you may encounter a problem such as a clogged well. You can deal with this problem yourself, you just need to choose the appropriate option.

The problem must be addressed from the moment the well’s normal operation ceases. Over time, the well becomes clogged with sand, silt, rust and other sediments.

Sand blockage

This problem can be encountered when the well is not drilled deeply and the water layer is adjacent to the sand and gravel layer. With proper arrangement, sand can penetrate inside the casing, but in a minimal amount.

Reasons for sand entering water:

- sand comes from the surface due to poor sealing of the head;

- large cells in the filter;

- loose threads, resulting in a lack of tightness between sections;

- the filter is damaged;

- mechanical failure of the pipe.

Small grains of sand are easier to remove; they are washed out a little when the water rises. It is more difficult to deal with large grains of sand; they settle and clog the well over time.

Siltation of the well

This problem is mainly faced by summer residents who use the well seasonally. During the autumn-winter period, particles of silt, rust from pipes, and grains of sand accumulate. The less the well works, the more it becomes clogged. Without regular maintenance, the well will become clogged with silt within a couple of years.

Methods for self-cleaning a well

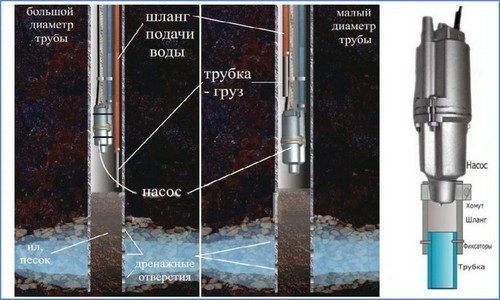

Pumping a well with a vibrating pump

The simplest, but not the most effective way to restore the operation of a well. The vibration pump cannot be used for a long time; circulation pumps are more suitable for cleaning the pipe from sand.

The reason is that the pump is unpretentious to the quality of water. It easily pumps water and sand, catching small debris, so the abrasive quickly breaks the check valve. Before cleaning the well, you need to make sure that the part is in good condition.

This part is not expensive and can be changed by hand within 5 minutes. The cost of a vibration pump is much less than water pumps. In the event of a breakdown, losses will be minimal.

This method will not help clear thick silt in the pipe, but it will do an excellent job of removing sand by removing most of it from the casing, from a shallow depth. At a depth of 30 meters or more, the pump’s performance decreases. It is worth considering that for cleaning a well, only a pump with a bottom liquid intake is suitable, which must be lowered onto the sand deposits, raised a couple of centimeters from the bottom, so that it collects contaminants more efficiently. As the sand is cleaned, you need to gradually lower the pump lower. You can work for no more than half an hour at a time, then a fifteen-minute break so that the pump can cool down.

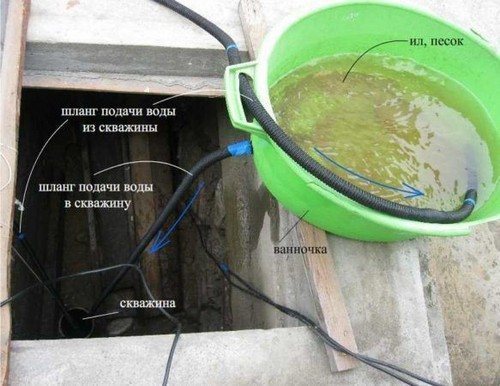

Flushing a well with a pump from the surface

An excellent way to remove small grains of sand, rust and other small contaminants is by pumping water into the well from the surface. To avoid dirt on your site, it is best to run the process in a circle.

You should not take water from an open reservoir.It is better to stock up on containers similar in volume to the casing pipe. The pump circulates liquid between the container and the well. As a result, contaminants begin to settle at the bottom of the container, which must be periodically removed using a pump. Reagents can be added. For example, phosphoric acid removes calcium deposits and rust. The acid is easily quenched with soda. After using the reagents, the well needs to be driven for several hours.

You can carry out the procedure without containers, but then you will need, for example, the neighbors' water supply and a place where dirty water will be poured.

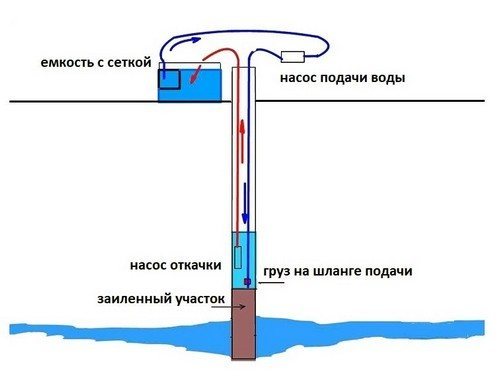

Flushing a well using two pumps

This method is used in wells with a depth of over 50 m, which are difficult to flush with the first and second methods. To do this, you will need a submersible and surface pump, two hoses, a water container, a bucket with holes and a cable.

The submersible pump must be lowered down the well and secured half a meter from the blockage. The hose must be lowered into a full barrel of water. The bucket is placed in the container, and the surface pump is lowered into it. Teeth from the fittings are attached to the hose of the surface pump using clamps, which should extend beyond the hose 20 cm. After that, the hose with baking powder must be placed on the bottom.

You need to start both pumps, moving the hose with fittings, up and down. The blockage will gradually disperse due to water pressure and additional impact.

Cleaning a well using a bailer

The easiest cleaning method, which requires good physical strength. This is hard and tedious work.

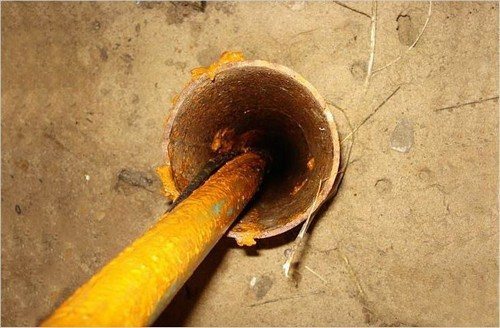

The bailer is made specifically for cleaning wells, but you can also make it yourself. To do this, you will need a piece of pipe - 60 cm, a disk with holes is welded into it, half the diameter of the pipe. On this side, you need to cut out teeth that will hit the blockage. You need to put a metal ball in the pipe, and fix a metal mesh on top.

The bailer must be fixed to the cable and placed in the pipe. You need to raise and lower the bailer to the very bottom of the well, periodically lifting it to clean it from accumulated dirt. Cleaning will occur due to the descent of a metal ball inside the pipe. It will descend more slowly, allowing water and dirt to penetrate inside, then the ball plugs the hole.

All of the listed methods are simple and effective in their own way, do not require large investments. In almost any case, you can deal with the blockage yourself. At the same time, do not forget about caution, because well repair is not a cheap pleasure.