Your washing machine won't spin the drum? Then let's look at the possible faults and how to repair them.

What to check first

First you need to check the availability of power. If other devices are working properly, then the source of the problem may be:

- the device is connected to a circuit breaker that was knocked out during a short circuit;

- There is a current leak in the electrical circuit. In such a situation, the residual current device will operate.

In this case, the control panel does not light up, and it is not possible to start the electrical network section. It is necessary to inspect the wiring for damage to the insulation. Before doing this, the wires must be de-energized. The malfunction can be identified using a special indicator.

Another common reason for the machine stopping is exceeding the critical weight. A special sensor is built into the device, which protects it from overload. Then the display will show an error message or the unit simply will not work. Fixing the problem is very easy: you just need to reduce the number of things, and next time follow the manufacturer’s recommendations.

Modern models can interrupt the wash and block the door if the drain filter is clogged. In this case, you need to unplug the device and clean the filter. It is located at the bottom of the front panel. You will need any container to drain the water.

The device stops functioning if the rubber hoses for supplying or draining water are damaged. As a result, liquid will leak onto the floor. You can replace pipes yourself, without involving specialists.

The reasons why the washing machine does not spin can be much more serious. Some can be repaired with your own hands, while others will require the involvement of a specialist and money.

There are two types of problems, depending on which drum:

- scrolls freely by hand, but does not rotate during startup;

- cannot be moved manually (jammed).

Each situation has different problems.

If the drum rotates freely

If rotations are present under the influence of external force, then breakdowns occur as follows:

- Damage to the belt (this item does not apply to direct drive models). A problem is indicated by noise from the engine, but the laundry does not spin. The belt can be inspected by removing the back panel. The part wears out both with active use of the unit, and during idle time it dries out and cracks. If the drive belt is frayed or loose, it must be replaced. Before purchasing a new belt yourself, you should study the markings of the old one. You need to find out its length and number of wedges.

- The motor brushes are worn out. With prolonged use, the brushes become shortened and no longer reach the commutator. As a result, the electromagnetic field necessary for rotor movement is not generated. During operation there will be no noise from the engine. When the brushes are completely worn out, they need to be replaced.

- A wiring fault in the device itself prevents voltage from being supplied to the motor.

- Problems with the electronic module or programmer. The first is installed in devices with electronic control, the second is typical for electromechanical. This means that the control board, which should transmit a signal about the start of washing, is not working. Malfunctions most often occur due to voltage surges in the network or forced manual adjustment of programmed operating modes. Repair consists of "reflashing" the old board or installing a new one. If there is simply a failure in the module, it is enough to perform the program reset procedure.

- Electric motor failure. Malfunctions with this part of the unit do not occur often. Basically, they occur during operation for more than ten years. Malfunctions occur due to power surges or leaks, as a result of which water gets into the engine. If there is a short circuit between the turns of the motor winding, the empty drum can rotate. However, when starting the device, the fuses will immediately knock out. A break in the winding will completely jam the machine, and it will not move at all. It is better to let a specialist solve this problem, who will carry out diagnostics and repair or replace the engine.

If the drum is jammed

When the washing machine is jammed, the nature of the malfunction differs from the above. The breakdowns are as follows:

- The drive belt has “flown off”. The belt could have wound around the pulley or gotten between it and the drum. Then rotation will be impossible. The problem occurs as a result of incorrect loading, loosening of the belt and bearing failure. Repair consists of replacing the non-working parts.

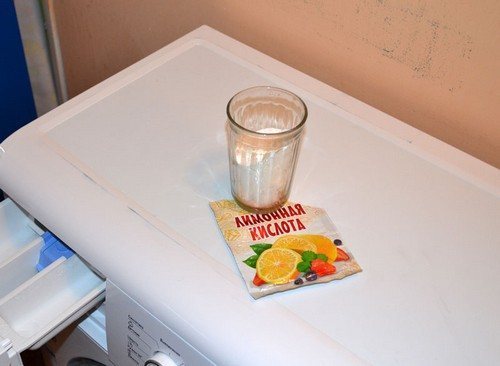

- Bearing failure. Over time, the bearing begins to rust and deteriorate.This occurs when the seal, whose function is to protect against water, loses its elasticity. Then it allows liquid and air to pass through. The reason for this is the excessive use of cleaning products. Once inside, water and soap cause corrosion. The defect may not be noticed immediately if the machine is actively used. A damp, rusty bearing will function for some time, but the operating device will produce a characteristic iron squeak. However, it is highly undesirable to use it, since a bearing destroyed during washing can cause serious damage to other parts. When the machine has not been used for 3-5 days, the bearing will dry out. Then the rust will have the properties of sandpaper, which is why the device will jam. A faulty bearing must be replaced along with the oil seal.

- Foreign object. The drum can jam if a foreign body is stuck between it and the tank. This situation occurs when a small object penetrates into the joint between the drum and the rubber cuff during spinning. A foreign object sometimes causes bearing or tube heater failure. Therefore, it is very important to check pockets for foreign objects. Small things, such as a baby's sock, also get lost. In this case, it is advisable to wash small items in separate mesh bags.

- Capacitor failure. This part is built near the engine in earlier models. In this case, the motor is working, but there will be no rotation. The capacitor must be replaced for normal operation of the motor.

- The tubular electric heater (TEH) has burned out. The danger is that the heating element can shatter into many fragments and stop the entire operation of the device.Therefore, you should carefully remove all the fragments and install a new electric heater.

- The doors opened. The situation is typical for models with vertical loading. If the machine was too loaded with laundry or something got caught in the latch, then the open doors cling to the electric heater. In this case, manual rotations are not possible. To fix the problem, you must disassemble the machine. If damaged, the part must be replaced.

To extend the life of your washing machine, you should follow the manufacturer's recommendations for loading laundry and the required amount of powder and cleaning agents. Also, carefully monitor unusual signals during the washing process to troubleshoot problems in a timely manner.